Horizontal Directional Drilling (HDD) is a trenchless construction method used to cross obstacles along a pipeline route, such as roads, rivers, and sensitive areas. This method minimizes environmental impact and avoids interruptions to the obstacles being crossed.

HDD applies proven directional drilling techniques from electricity, oil, and gas well drilling to steer a drill bit beneath an obstacle along a planned pathway. This pathway is later enlarged to install a pipeline or conduit under the obstacle.

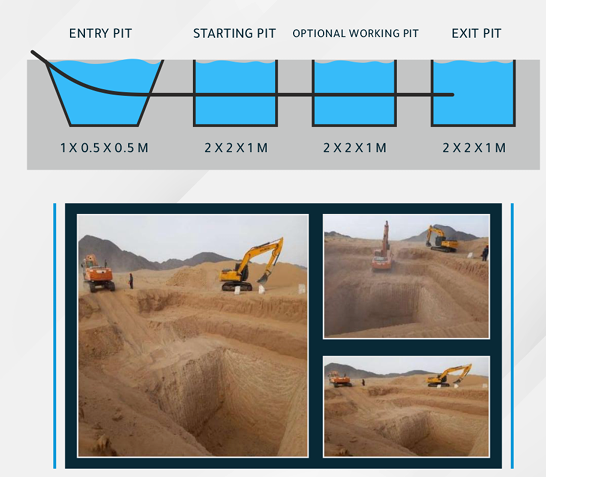

A cross-sectional diagram illustrates the layout of pits required for HDD work. Pit sizes are calculated based on the bore length and size.

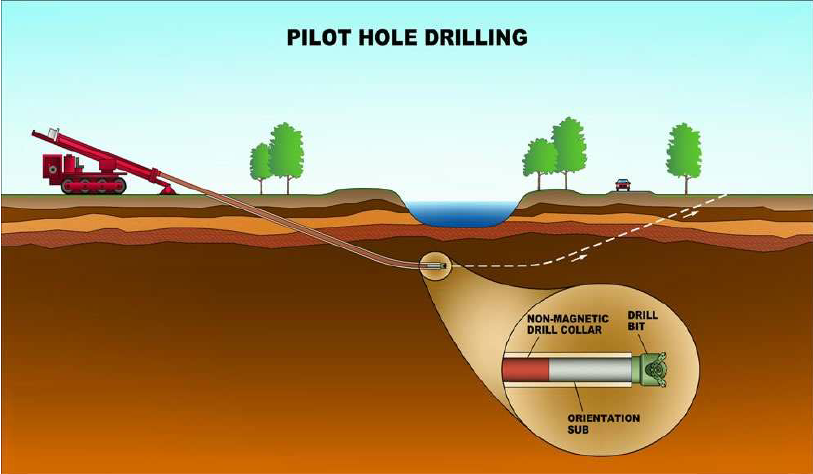

A small-diameter pilot hole is drilled with directionally controllable tools, following a planned profile. Specialized cutting heads and directional control devices ensure precision.

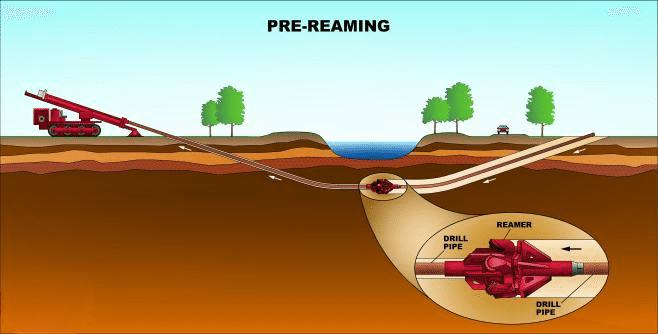

The pilot hole is enlarged using reamers to allow for the installation of the product pipe. This process may involve multiple passes with different reamers suited for varying ground conditions.

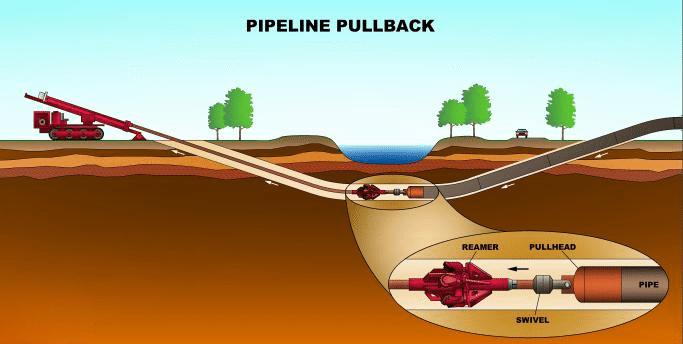

The pipeline is prepared as a continuous string, laid on a launching ramp with roller supports to minimize friction. After jointing and coating, the pipe is pulled back into the reamed hole.

A radiosonde system continuously transmits the cutting head's position and orientation using electromagnetic waves, assisting the drilling crew in steering the drill.

The drilling fluid, a water and bentonite mix, is prepared in a mixing unit with double tanks holding up to 4000 liters of fluid. High-pressure pumps ensure efficient circulation during drilling.

HDPE (High-Density Polyethylene) pipes are joined using the butt-welding process, which involves:

HDPE pipes can be pulled in bundles if all segments have similar physical properties. Bundles are strapped securely to withstand tension during installation. Pressure tests are conducted after bundling to ensure the integrity of the strapping.

All rights reserved © MICC